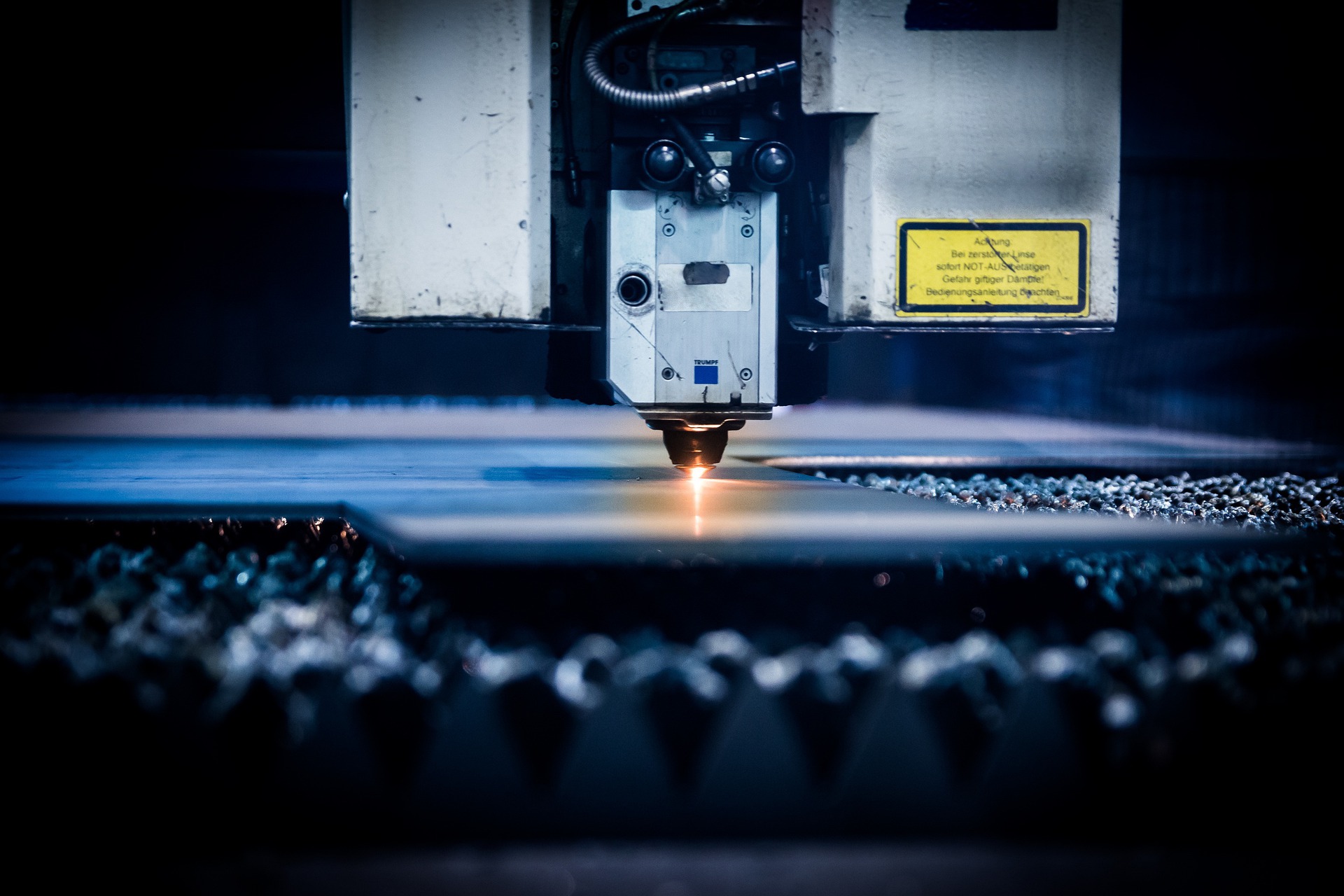

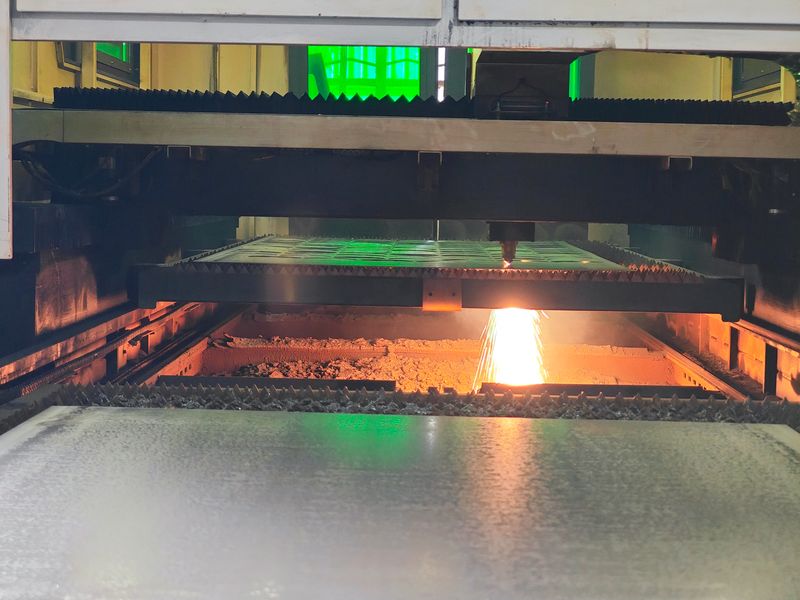

Forming process

During the extrusion/stamping process of the guide rail, the straightness of the whole process is monitored by laser to ensure that the track is straight and without distortion

Spraying

After surface treatment electrostatic spraying, 100% check the adhesion and wear resistance of the coating

Simulation

Simulate the long-term sliding of the door body, and conduct 10,000 reciprocating tests to verify the amount of track wear and deformation

Extreme test

Pulley material through low temperature brittleness and high temperature aging test, adapt to extreme environment

Accuracy test

Each pulley is tested by starting power to ensure smooth pushing and pulling without stalling